Portfolio for Marine Applications

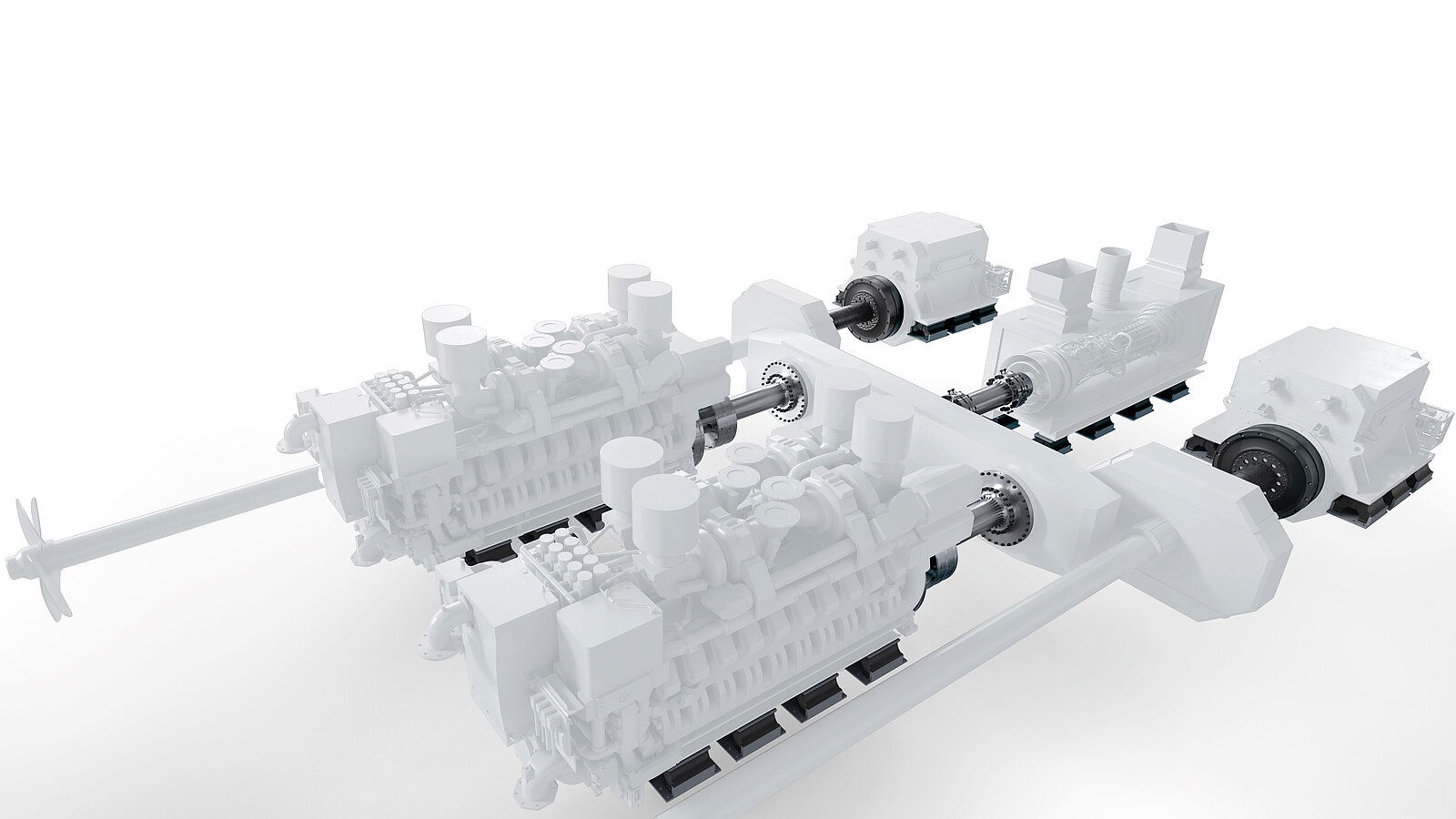

VULKAN delivers complete coupling and mount solutions for the full range of naval propulsion architectures – from CODAD, CODOG, CODAG, CODOE, and hybrid to CODELAG systems. Our portfolio covers high-performance flexible couplings and resilient mounts, engineered to meet the most demanding naval requirements for torque transmission, vibration isolation, shock resistance, and acoustic signature reduction.

The propulsion concept shown here demonstrates our capability to serve a variety of prime movers within one integrated system layout. Whether under medium-to-high-speed diesel engines, quiet-running electric drives, powerful gas turbines or gensets, VULKAN solutions provide precise torque transmission while controlling vibration and reducing structure-borne noise. Flexible couplings manage torque transmission, torsional dynamics and misalignment/displacements under varying load conditions, while resilient mounts isolate propulsion equipment from the ship’s structure, protecting sensitive systems, enhancing crew comfort and safeguarding mission success.

Our role extends far beyond component supply. We engage with shipyards, naval architects, consultants and system integrators at the earliest design stage, ensuring that propulsion system layouts are optimized from the outset. This approach allows us to align mechanical performance, acoustic stealth, shock resilience, and through-life maintainability with each vessel’s operational profile and mission objectives. Leveraging decades of experience in flexible rubber couplings, resilient mounts, torsional vibration analysis, noise and vibration control and naval shock qualification, our engineering teams design and validate complete coupling–mount configurations for engines, gearboxes, electric motors, gensets and auxiliary equipment. Each solution is precisely tuned to the vessel’s propulsion concept, whether for endurance missions, stealth hunting missions, high-speed interception, or multi-role naval operations.

From initial concept development through detailed design, installation support and lifecycle service, VULKAN ensures that systems work better.

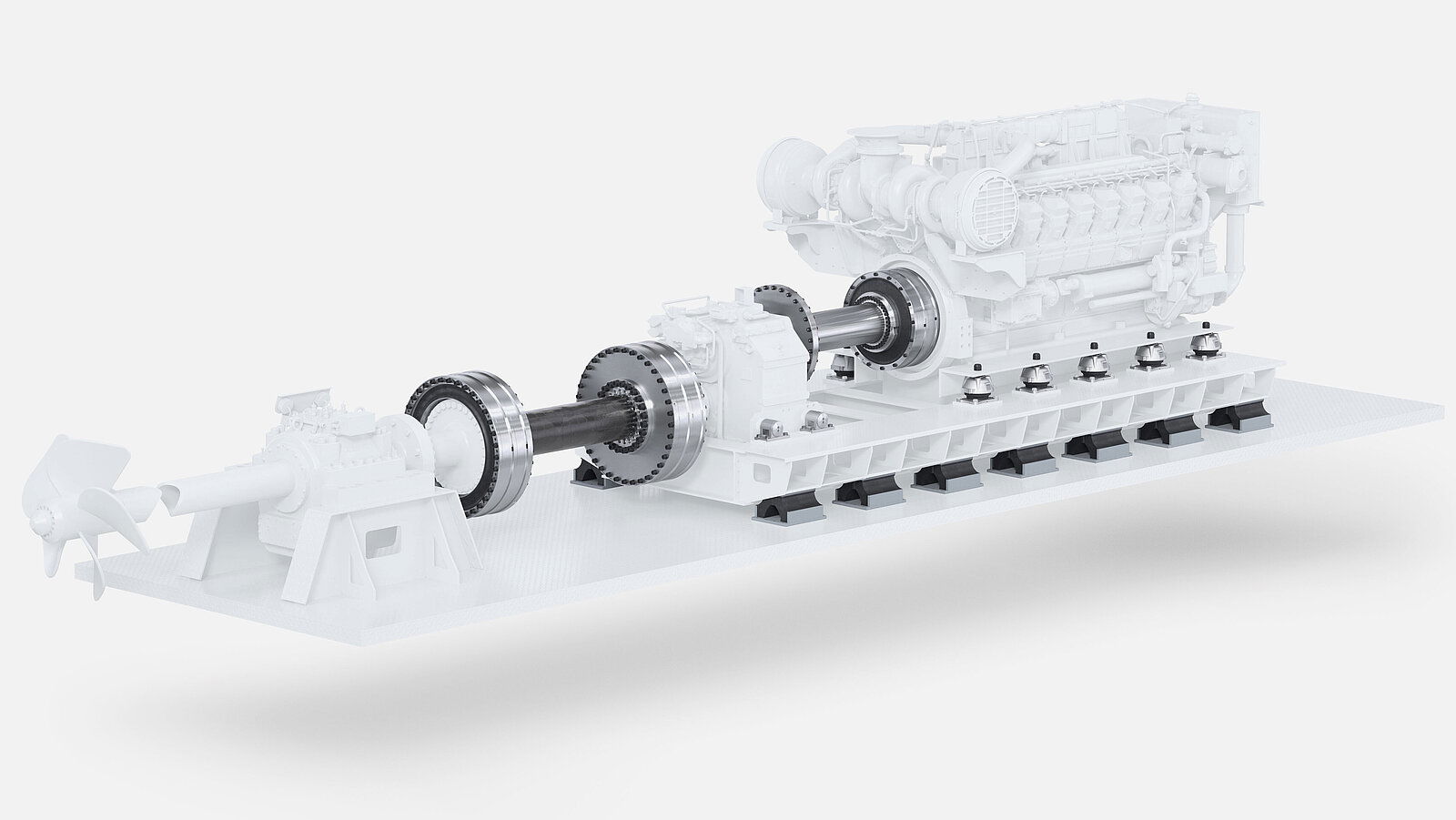

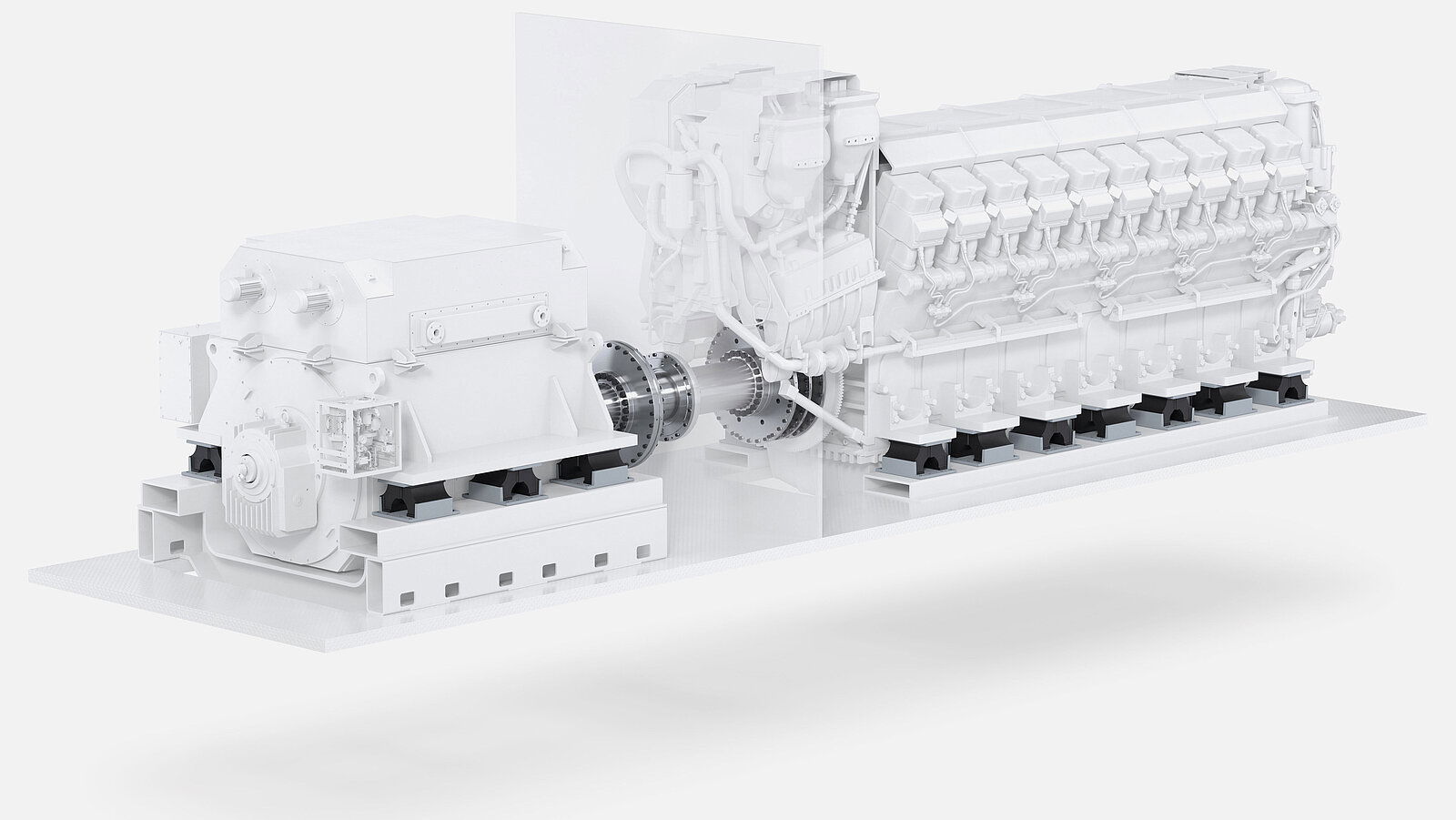

Double elastic mounted drive systems represent an advanced solution for effectively isolating structure-borne noise and vibrations originating from reciprocating IC engines, through the strategic use of resilient mounts beneath both engine and gearbox as well as below the common baseframe.

VULKAN’s specialized engineering expertise ensures the optimal selection, placement and stiffness of mounts, carefully matched with precisely engineered couplings. Especially VULKAN’s acoustically optimized couplings downstream of the gearbox, properly tuned with the navy-optimized main diesel engine coupling, further enhance noise and vibration performance. Backed by decades of product characterization measurements and deep experience in vibro-acoustic analyses, VULKAN’s navy experts tailor mounts and couplings for maximum effectiveness. This includes advanced 12 DOF, 18 DOF and structural simulations to accurately calibrate system behavior for effective displacement compensation, robust shock resistance and smooth torque transmission under demanding sea-going and mission-critical shock conditions. With VULKAN solutions onboard, shipyards, integrators, and engine manufacturers can significantly enhance the acoustic signature, reliability and operational readiness of naval vessels.

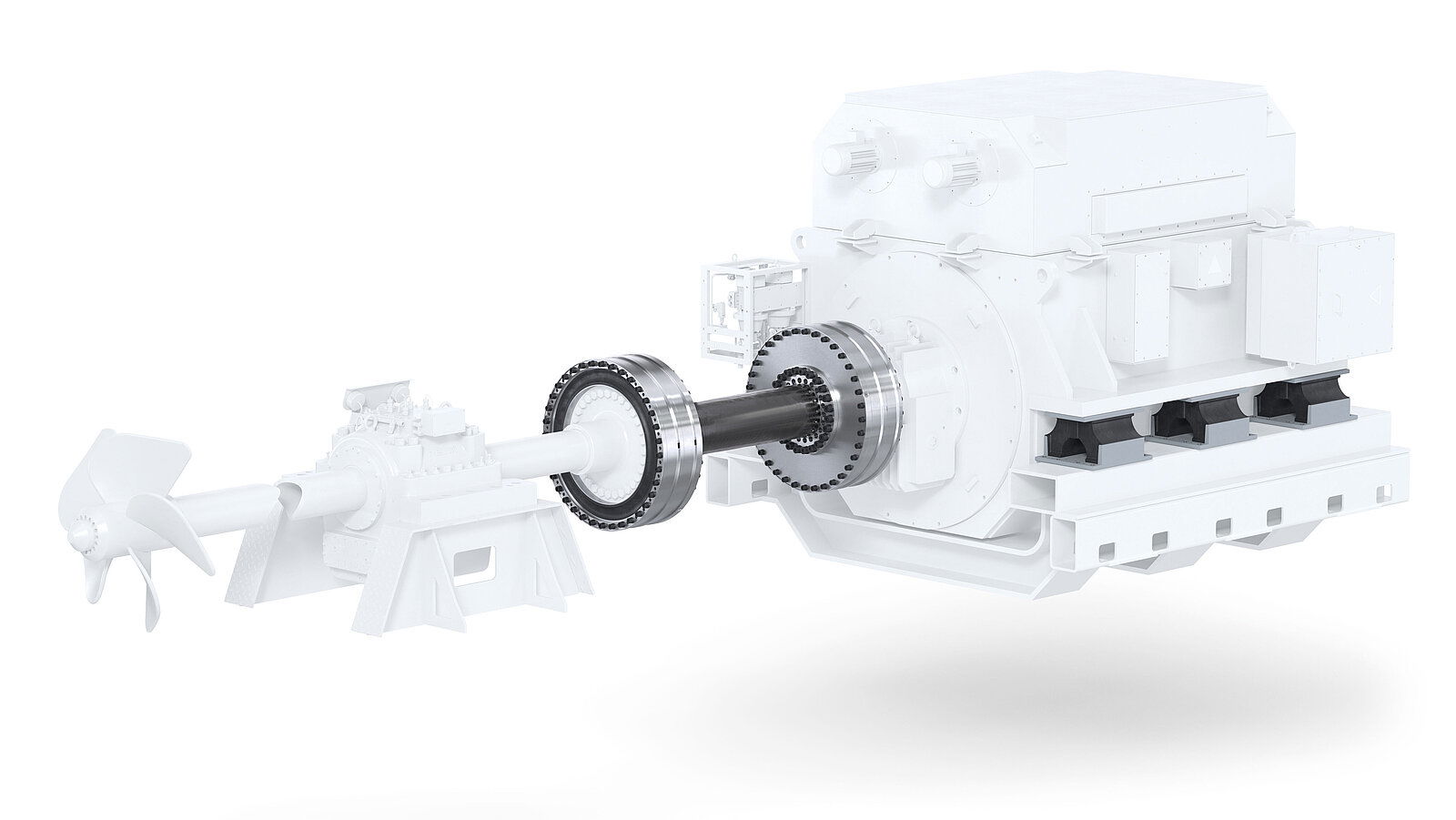

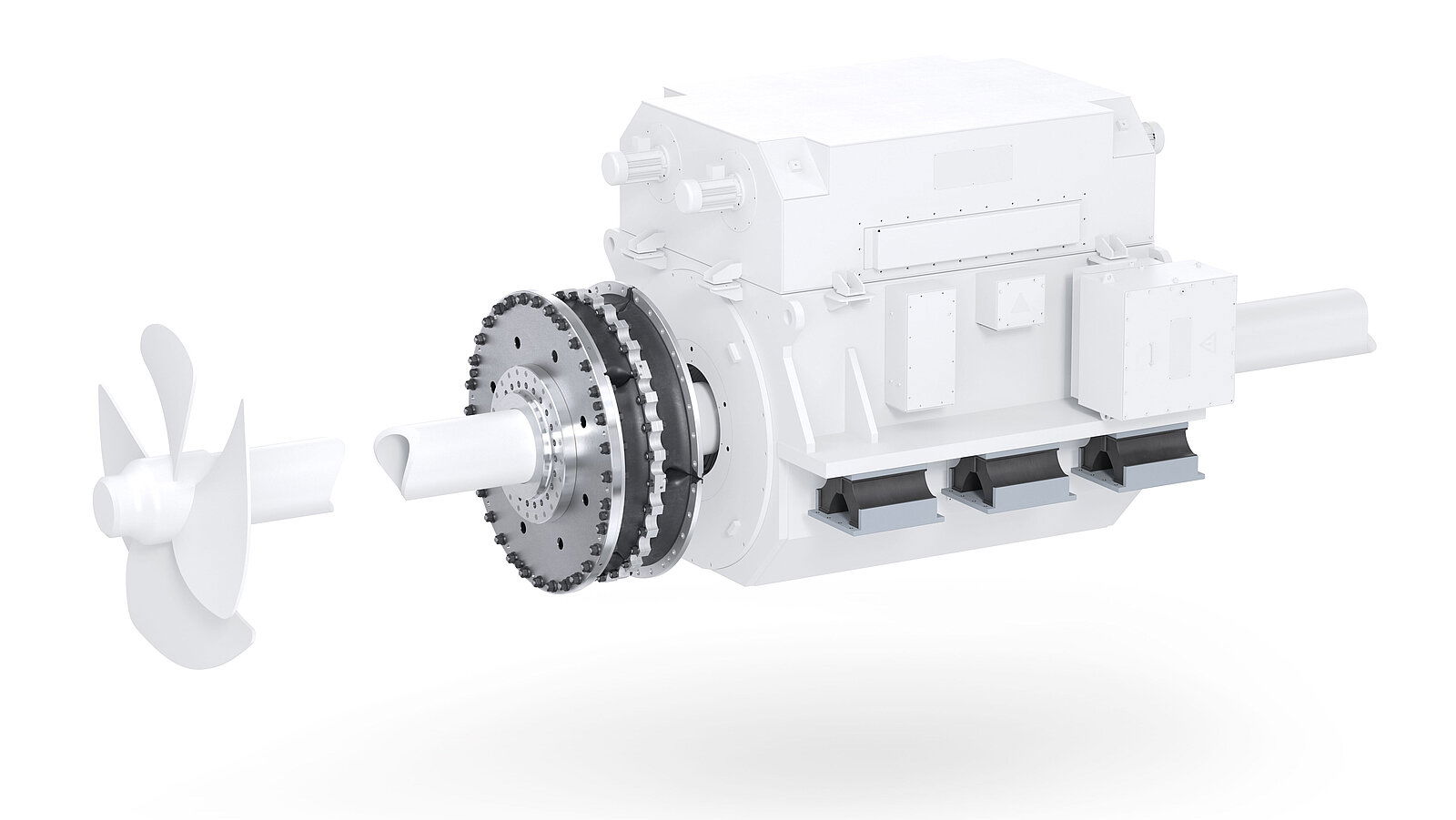

E-Drive propulsion systems are increasingly employed in modern naval vessels, offering silent operation for stealth capabilities and flexible mission-critical operational modes. Utilizing electric motors in main propulsion drives or also in PTO/PTI configurations, vessels seamlessly switch between efficient power generation and quiet electric propulsion, significantly reducing acoustic signatures. VULKAN’s specialized engineering expertise ensures the optimal integration of mounts and couplings in electric propulsion arrangements. Drawing upon our comprehensive product characterization data and extensive experience in shock analysis and vibro-acoustics (including advanced 6 DOF and time-domain shock simulations), VULKAN precisely matches resilient mounts and couplings, acoustically optimized to the unique vibration profile and torque demands of E-Drives.

Our solutions reliably isolate motor vibrations, compensate displacements and ensure smooth, noisereduced torque transmission. This holistic engineering approach guarantees maximum reliability, superior shock resistance and enhanced vessel mission-readiness.

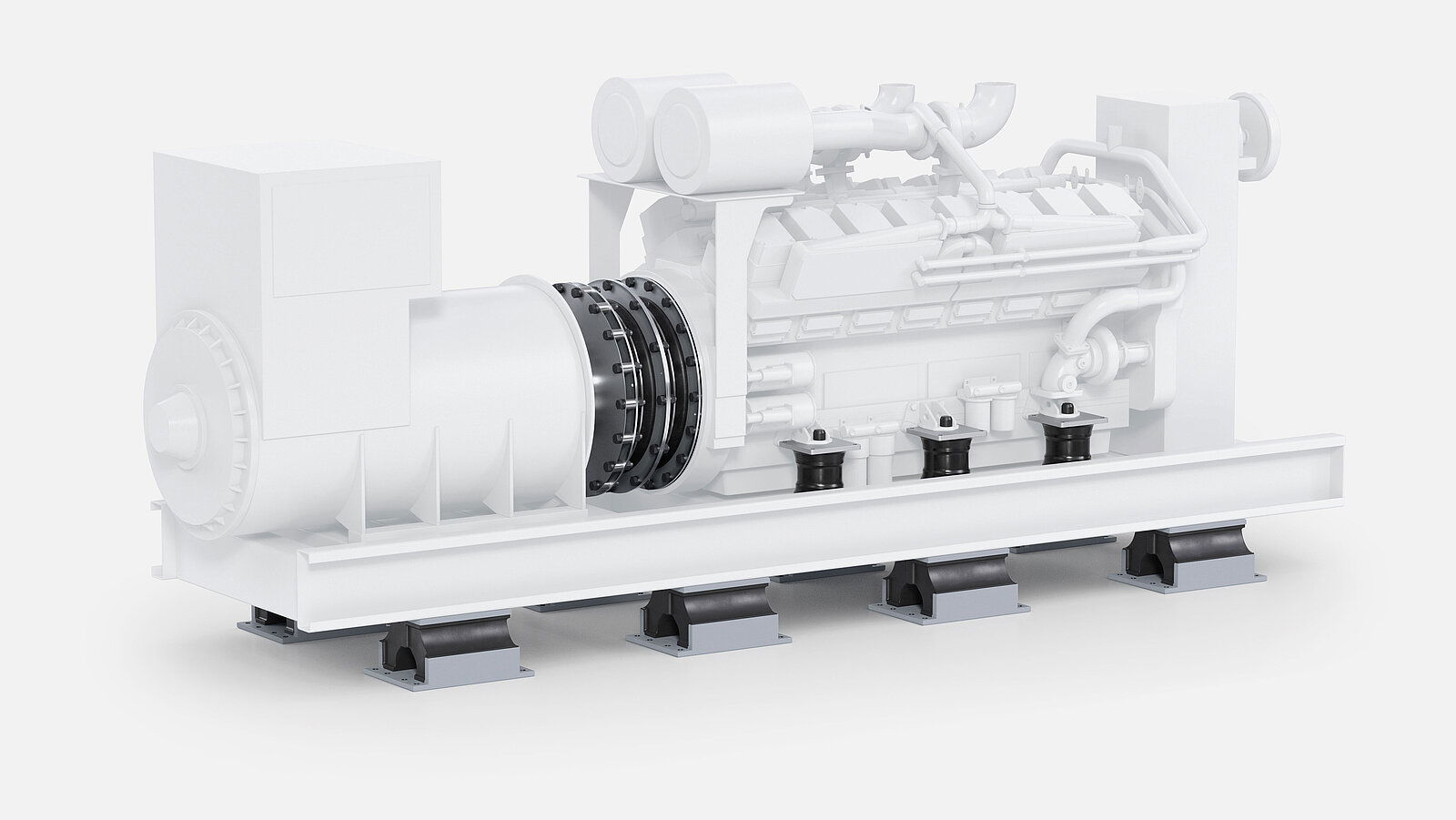

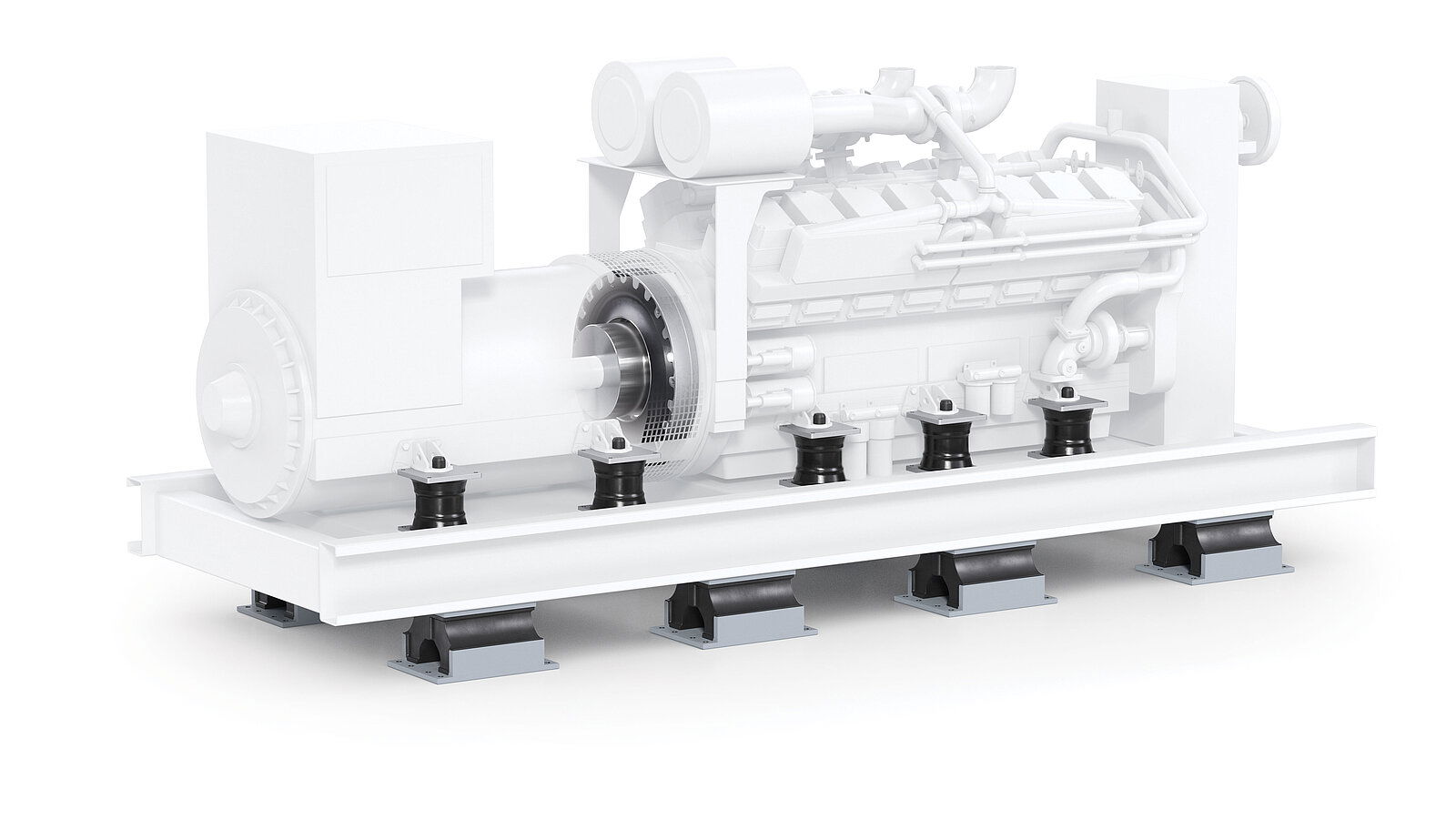

Generator sets onboard ships deliver electrical power for auxiliary and propulsion systems.

For naval vessels single or double resiliently mounted setups are used. In general the lower layer of shock mounts are able to take up the shock load and isolate structure borne noise from engine and alternator to ship foundation. The optional upper layer of mounts increases the level of structure borne noise isolation.

The resilient mounting configuration shown is common practice when the alternator is chosen specifically for the project. The double resilient mounting underneath the engine ensures maximum isolation of structure borne noise from the dominant source. Furthermore engine vibrations are isolated towards the alternator, which ensures low vibration levels on the alternator. When needed the alternator can be resiliently mounted on the frame as well.

The coupling in-between engine and alternator compensates for radial and axial displacements during shock and seaway motions.

A single or double resiliently mounted genset with close-coupled alternator is mostly used for standard and lower rated gensets. Premium structure borne noise isolation can be achieved with this setup against the lowest weight. In this configuration the coupling doesn’t need to compensate for radial and axial displacements during shock and seaway motions.

A 6 or 12 degree-of-freedom calculation, respectively for a single or double resiliently mounted setup, shows the static and dynamic behaviour of the genset. An additional shock calculation shows the behaviour of the genset during shock. Structure borne noise isolation can also be predicted in an acoustic analysis. These calculations ensure the project requirements are met on vibration, shock and structure borne noise.

In this specialized configuration, the diesel engine and alternator are positioned on opposite sides of a bulkhead and mounted on separate resilient mounting systems. As a result, a conventional genset with a common frame cannot be used; instead, the engine and alternator are installed independently, each with its own shock-qualified mount arrangement. This separation allows each unit to move independently under shock or sea-going operational loads, creating far more complex dynamics, displacement and alignment challenges than in traditional skid-mounted gensets (skid-mounted refers to both engine and alternator being rigidly fixed to a common baseframe, moving as one unit).

The flexible coupling must transmit torque reliably while accommodating multi-axis relative movements. The bulkhead seal, usually as part of VULKAN’s scope of supply, must maintain sealing integrity despite complex shock displacements as well as continuous relative motion during normal sea-going conditions.

Meeting these combined demands calls for advanced simulation tools, precise tuning of coupling characteristics, proven shock qualification expertise and deep competence in marine bulkhead sealing technology.

Modern drive concepts typically show a combination of diesel engines, electric drives, gensets and/or gas turbines. This ensures the best performance in each of the operational modes. Experienced VULKAN specialists analyze, harmonize and coordinate the systems with each other. Especially integrating hollow shaft electric motors requires a lot more attention. Shock requirements and radial displacements have to be coordinated with the available space between coupling and propulsion shaft. Also ship motion has a significant impact on the design. Most important is the communication in the early design phase between electric motor manufacturer and VULKAN – observing the optimized mount position on the electric motor leads to improved displacement capabilities of the entire system.

The focus here is on the vibration assessment of the overall system, the transmission of structure borne noise and resilience in the event of shock. These meet the highest acoustic and demanding shock requirements. Special designs are also available in non-magnetic materials.

As every project has its specific requirements we encourage our customers to get in contact and find the best solution together.