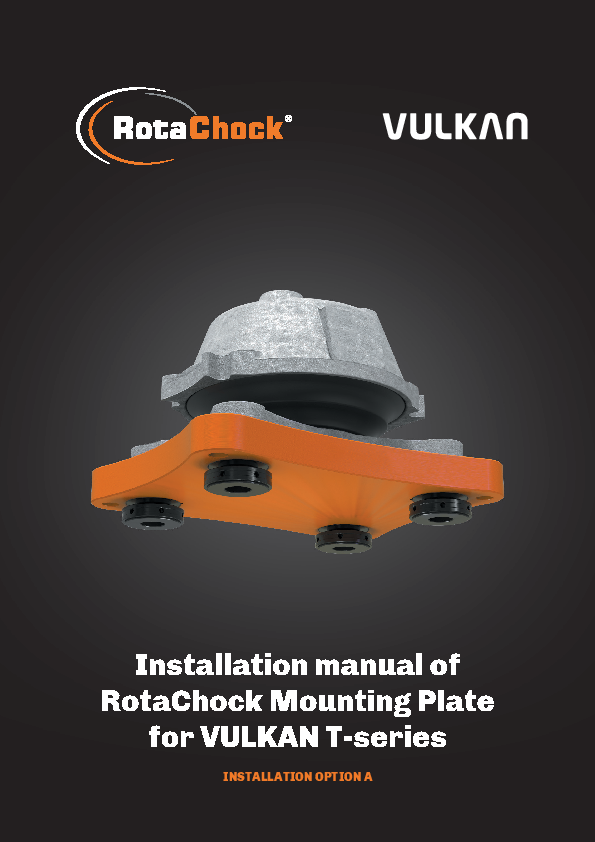

RotaChock Mounting Plate

Achieving precise alignment of rubber mounts can be a complex task. Ensuring the base plate of the mount is perfectly parallel to the machine foot is crucial for effective vibration damping.

Traditionally, this involved using four adjustment bolts to eliminate any angle between the cap and the base plate. Next, filling the gap between the mount's base plate and the foundation using two-component epoxy resin or custom-made steel-fitted blocks.

Say goodbye to these complexities because the RotaChock Mounting Plate offers an economical alternative. By utilizing the adjustment bolts in the RotaChock Mounting Plate, you can eliminate any angle between the mount's foundation and base plate. Next, the four RotaChocks positioned at the corners effectively fill the gap. Securely tighten the base plate, RotaChock Mounting Plate, and machine foundation together using four foundation bolts.

Additionally, with the RotaChock Mounting Plate, the mounting system can be readjusted whenever needed. Simply loosen the foundation bolts and make necessary adjustments to the RotaChock to achieve your target alignment. This allows for major time savings, reducing the typical installation time for a resiliently mounted machine from several days to just a few hours.

Benefits

- The best rigid chock for resilient mounts to prevent Soft-Foot

- With RotaChock you will always have the possibility to readjust your alignment

- It’s user friendly – no special training or tools are required

- Standard design with adjustability range, engineering free

- RotaChock saves time over epoxy resins and steel-fitted chocks

- Type Approved by leading classification societies

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/4/csm_RotaChock_Mounting_Plate_ebf6ae3a5a.jpg)